Comparison of laser printer and ink printer

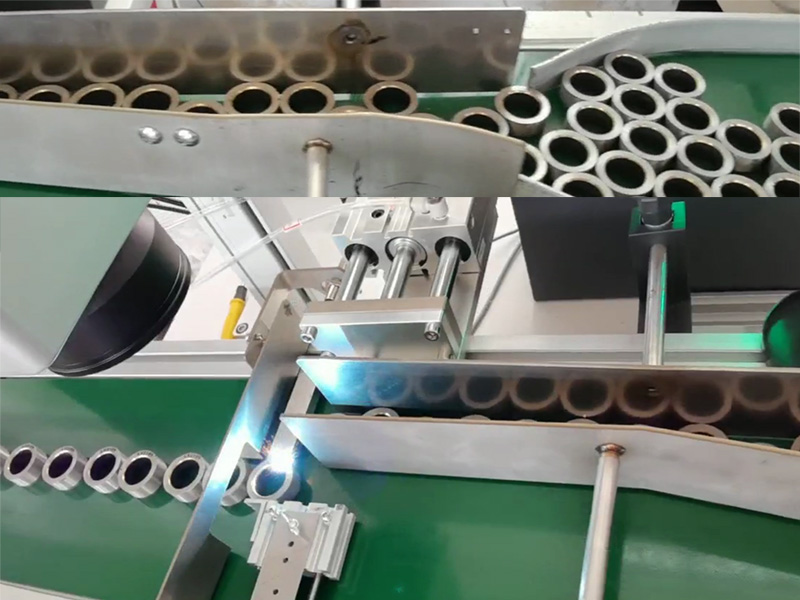

Flying laser marking machine, also known as online laser marking machine, laser printer, is a high-tech product developed and designed by our company for online marking of product packaging, pipes, and wires in various industries. It can be selected according to the different needs of customers. Fiber laser, semiconductor laser, CO2 laser, and ultraviolet laser and other models are combined with automatic assembly line worktable to meet the flight marking system required by customers to realize assembly line operation and improve production efficiency.

Industry application:

It is widely used in tobacco, food, medicine, dairy products, drinking water, alcohol, daily necessities, cables, pipes, wooden floors, electronics, home appliances and other industries.

Applicable materials: applicable to most packaging materials and all metals, most non-metallic products.

Product advantages:

·Automatic feeding equipment is combined with laser marking machine, the equipment has good stability;

·Can cooperate with PLC equipment to complete higher automation action requirements;

· Rich communication mode of network port and serial port, which is convenient to integrate more intelligent control system;

·Adapt to customers' large batch and continuous production, with high production efficiency;

The software can automatically generate serial numbers (barcodes, two-dimensional codes and other common code systems), which are used to achieve unique identification, mass production, and easy-to-trace product marking, which has good anti-counterfeiting and anti-channeling effects;

Compared with traditional ink coding, it has a large printing range, high efficiency, portability, and no consumables. The advantages of non-toxic, non-polluting, maintenance-free, permanent marking and not easy to erase;

It can directly cooperate with the customer's production line operations. If necessary, it can also customize the assembly line or workbench and other intelligent human-computer interaction interfaces to make marking easier and easier.