Release date:2020-06-13 14:10 Browse times:

The industrial era relied heavily on tangible physical resources such as land, labor, raw materials, and capital, while the information era began to vigorously develop and use intangible information and knowledge resources such as data, information, and images. Laser marking is also constantly breaking through to adapt to the development of society, gradually replacing the traditional screen printing process, and bringing new vitality to the manufacturing industry in a more convenient way. Industrial laser marking processing is increasingly trusted by many companies.

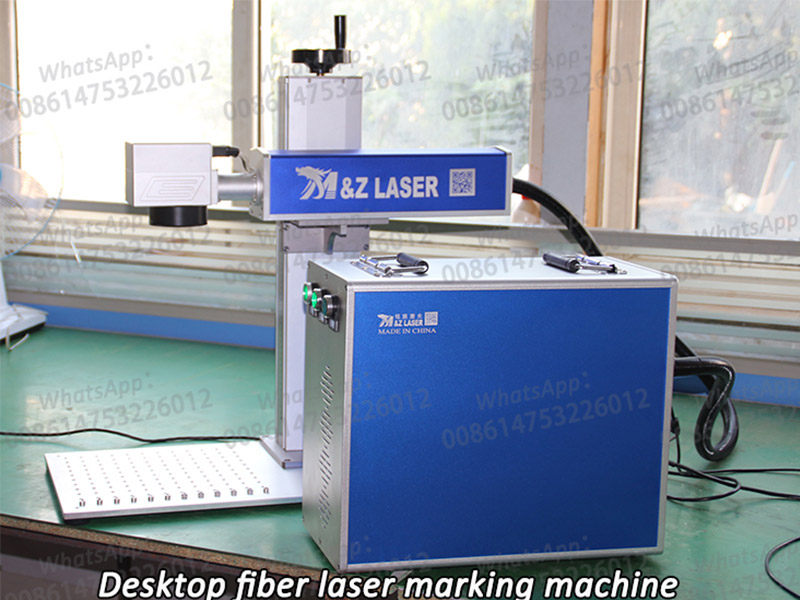

The below is the machine picture of fiber laser engraving machine

Laser marking machine has been applied to product marking in many industries. Laser marking machine thermal processing technology: using a laser beam with high energy density and concentrated, irradiating the processed material (metal, plastic, wood, etc.) On the surface of the material, the surface of the material absorbs laser energy, and a thermal excitation process is generated in the irradiation area, thereby causing the temperature of the surface (or coating) of the material to rise, causing metamorphosis, melting, ablation, evaporation, etc., and finally forming a preset marking effect Because it uses high temperature to achieve the desired effect, it is called thermal processing; for example: fiber laser marking machine and co2 laser marking machine. There are also cold processing, such as uv ultraviolet laser marking machine, which is considered to be cold processing, which is less affected by heat, and the marking effect is more perfect.

If you have any questions, add my friends

Skype:hellomike00